Interview with the 8th issue of the "China Famous Enterprise" column of China Report Network: Deng Nanyue

Release time:

2018-09-13 10:02

(Dongguan, Guangdong Province): Foreword: In Dongguan, there is a legendary "person", he was called "aluminum wheel expert" by the industry. He is the general manager of Dongguan Nanyue Mould Die Casting Co., Ltd. (referred to as Nanyue Company)

Deng Nanyue: Executive Vice President of Hunan Hengnan Chamber of Commerce in Dongguan, graduated from Tsinghua University, majoring in international business administration. In 1989, he came to Guangdong to engage in the construction industry. In 1992, he entered Tongda Plastics, and he was an executive from ordinary employees. At the age of 32 (1997) In the year of 2007, he became a mold processing shop with two partners, and founded Nanyue Company in 2007. When he was young, he showed his ability to do business. He finally had a stage to try his hand. He also uses his own knowledge to sharpen his own will in the market, diversify learning techniques, and gradually enrich his "thought and mind." With the courage and keen business sense, Deng Nanyue constantly seeks his own development goals, and confidently stepped into the road of entrepreneurship.

Reporter: What kind of company is your company?

General Manager Deng Nanyue: Nanyue Company is a professional manufacturer integrating precision die-casting mold design and manufacturing, professional design, production, processing and sales of cable machinery equipment parts and zinc-aluminum alloy die-casting products. Founded in 2007, the registered capital is 5 million. With the changes in the market situation, our company has gradually grown into an innovative company with independent brands focusing on the design, production and sales of professional aluminum wheels. The company has set up its own R&D team, and we launch new designs every year from time to time. It provides a full range of a wide range of storage wheels, guide wheels, meter wheels, take-up wheels, fiber guide wheels, and lacquer machine guide wheels to the whole country and the world. The company is now the vice president unit of Guangdong Wire and Cable Industry Association, the vice president unit of Greater China Wire and Cable Association, the executive vice president unit of Hunan Hengnan Chamber of Commerce, and the member of Hardware Mould Association.

Reporter: You are an entrepreneur who is self-reliant and self-reliant and innovative. Please talk about the values at the beginning of the venture.

General Manager Deng Nanyue: At that time, there were not many domestic aluminum wheel manufacturers. I think this is a huge business opportunity. So the South Moon Company was incorporated. From business registration to formalities, from company location to equipment installation and commissioning, from employee recruitment to start-up and production, almost all of my affairs are taken over. In addition, we must find ways to solve the financial problems of the company and run the market ourselves. "I don't think it's hard to think about it now, because we are young, full of the passion of the officers, and full of energy." Deng Nanyue recalled that in the past, he always smiled and paid for it. With continuous efforts, the company's reputation has started very quickly, and its product sales have increased significantly year after year. While creating economic value, it has also helped many people achieve employment.

Reporter: What are your business scope? What brands?

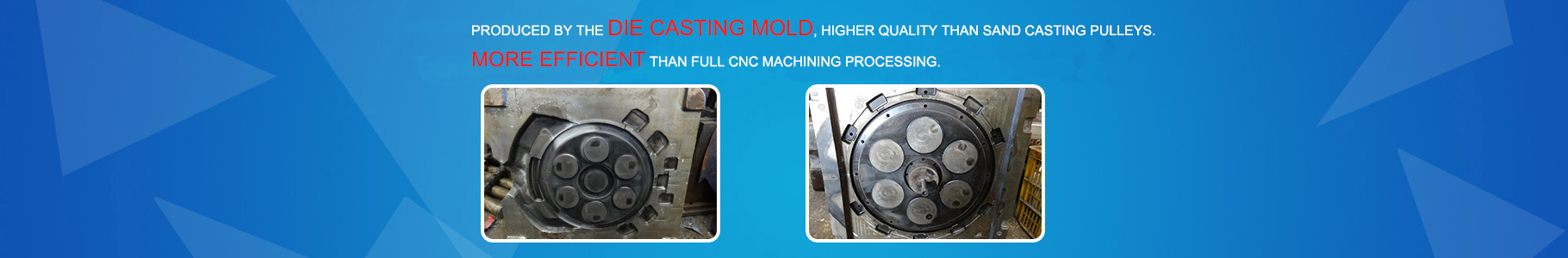

General Manager Deng Nanyue: From the first day of the factory construction, I know the importance of technological innovation to the development of the company. In the past few years, the company has developed hundreds of wheel products under the research and development of the R&D team. The products are equipped with wheels of well-known brands at home and abroad, and are sold well in many countries and regions at home and abroad and all over the country. In 2013, I led the core technical team to conduct market research through various exhibitions. Using our original mold die-casting technology advantages, we designed and developed high-precision aluminum wheel die-casting molds, using precision die-casting technology to produce aluminum wheels in various industries, subverting The traditional aluminum rod processing and low-pressure casting process in the cable industry have filled the gap in the industry. The company has obtained 12 utility model patents and 3 invention patents. Nowadays, the company continuously develops new products every year and pushes them to the market to meet the diversified needs of our customers. We are committed to building a cable equipment accessories supermarket, and we will fight for it.

Reporter: Mr. Deng, you have always stressed the importance of learning and what you have brought to you in your studies.

General Manager Deng Nanyue: In 2010, through his own study, he led his family to learn and led the company team to study together. Especially after learning the brand strategy in Victoria Master Class in 2012, I really felt the influence of culture on the economy. I believe that the demand for high-end products in the aluminum wheel market will increase in the future. I believe that choice is greater than effort, continuous innovation, persistence in learning, learning is the source of innovation, and change thinking through learning.

Reporter: Please talk about the views on the Chinese aluminum wheel market.

General Manager Deng Nanyue: Wheels are a culture. Now with the development of the domestic market, this culture has begun to sprout and develop in China. For the industry's consumers, the wheel industry has fully met their individual needs. For us, wheels are one of the most important parts in the industry. Therefore, Nanyue Company is committed to let domestic and foreign consumers know that good wheels, Nanyue, and the cable equipment accessories supermarket around you.

Reporter: What is the future development plan for China's wheels?

General Manager Deng Nanyue: At present, the aluminum wheels produced by the low-pressure casting process are still the world's largest. However, the high-precision die-casting technology will be the future development direction of the aluminum wheel industry. We have our own R&D team, and we launch new designs every year from time to time. As of 2017, we have more than a thousand orderers across the country, relying on the rise of emerging markets, we will promote products to more regions in the next few years. In the next step, it plans to invest funds to expand its own brand R&D technology center and establish a product testing center, and actively participate in the formulation of industry standards for aluminum wheel manufacturing to seize the commanding heights of the industry.

Reporter: Mr. Deng, your company is developing so fast, what do you rely on?

General Manager Deng Nanyue: We always adhere to the style of “serious, fast, persistent commitment, and guarantee to complete the task”; the cultural management philosophy of “integrity, harmony, innovation, and transcendence” and the principle of “joining together, never giving up, casting brilliant” Corporate mission; at the same time, culture is the spirit of the company. We integrate this spirit into the company's business philosophy and will strive to become a benchmark enterprise in the aluminum wheel manufacturing industry. The company's automated production line realizes real-time feedback on production data and, at the same time, adopts With international leading technology and equipment, it is a modern production line integrating informationization, intelligence, energy conservation and environmental protection, circular economy and efficient operation. "In 2018, we have to reach a higher historical level. "In order to master the core technology to produce high-end wheels, I have admitted that "there are always more difficulties than the difficulties." We want to be a world brand product, and we plan to consider listing in 2020.

Reporter: The company is a high-profile company. What do you think is the key point in management?

General Manager Deng Nanyue: I believe that the company needs to be transformed and upgraded, and the focus is on the construction of the talent team. The construction of the talent team will bring high returns. At present, the casting technology and equipment mastered by “Nanyue Company” can not only save more than 10% of aluminum in the process of casting, but also increase the strength of the wheel by more than 10%. After the energy saving, emission reduction, innovation, transformation and upgrading of the South Moon wheel, the direct cost savings for consumers is 50%, which has contributed to the national energy conservation. The company manufactures aluminum for the wheels every year. After casting new technology, it can save aluminum and directly reduce costs. In particular, the traditional aluminum rod processing and sanding process in the cable industry fills the gap in the industry. At present, the South Moon wheel has become a standard part of the industry project.

Reporter: Please tell Mr. Deng to the consumers about the production process and advantages of the Nanyue aluminum wheel.

General Manager Deng Nanyue: Well, the traditional aluminum wheels are directly milled and milled with aluminum rods or made of simple wheel body blanks by low-pressure casting process, and then machined and milled. Low-pressure casting knows that it is a simple casting process, that is, the molten metal liquid flows into the hub mold by its own gravity, and the liquid is filled after the liquid is filled with the whole mold. Since it is filled by the gravity of the liquid itself, it is easy to appear. For example, the appearance is rough, unsightly, loose structure, large pores, easy to wear, prone to breakage and the like. The traditional processing technology has the following problems and shortcomings: 1: Aluminum rods can not save raw materials, and the simple wheel blanks made by the low-pressure casting process can only save a small amount of raw materials and directly increase the cost of raw materials. 2: Lathe cutting processing has a large margin, long processing time, low efficiency, high labor cost, and directly increases the processing cost of lathe. 3: The aluminum wheel product made by the low-pressure casting process has a rough appearance, is not beautiful, has a loose structure, has large pores, is easy to wear, and is prone to breakage. 4: There is no uniform standard specification and size, which is not suitable for mass production, and it is not convenient for users to purchase and replace.

Nanyue company aluminum wheel production process: 1 product design → 2 mold design → 3 mold production → 4 high precision die casting → 5CNC lathe finishing → 6 surface treatment. We design and manufacture high-precision aluminum wheel die-casting molds by designing aluminum wheel products conforming to standard specifications and sizes, so that the appearance of aluminum wheel products is exquisite and meticulous, the appearance is beautiful and the size is accurate, and the turning allowance is only required for CNC finishing. The unilateral edge is 0.3-0.5MM, which directly saves the cost of purchasing raw materials by 20-50%. The lathe processing time is short and the efficiency is high, which directly reduces the CNC lathe finishing cost. The high-precision die-casting technology is adopted to ensure the tight structure and no pores. Compared with the low-pressure casting process, the aluminum wheel products have significantly improved wear resistance and bearing strength, which can prolong their service life and improve mechanical working efficiency. Brought to the wire, cable equipment, electrical machinery manufacturers: save money (reduce production costs) save time (improve work efficiency) worry (close structure, no porosity, quality assurance), the industry's unanimous recognition, to achieve uniform standards And size, suitable for mass production, convenient for users to buy and replace.

Summary: During the interview, the reporter accidentally discovered a book on the desk of General Manager Deng Nanyue, "Capturing the New Third Board - Interpretation of New Deal and Case Collection". It turned out that Deng Nanyue, who was born in the class, was seeking and preparing for the listing of the company. In his eyes, the aluminum wheel is his eternal cause, and Deng Nanyue wants to present the unique wheel to the world. (The Deputy Editor-in-Chief of this website: Luo Huiqing)

RELATED NEWS

NanYue Mould Die-casting Exhibition

NabYue would like to thank friends at home and abroad for visiting our exhibition and thanking all the friends who care and support Nanyue. Thank you for your support and trust! I hope that in the

OnSeptember8,2018,DongguanNanyueMouldDieCastingCo.,Ltd.heldanewproductandnewtechnologyappraisalmeetinginChangshaShangshaHuashengInternationalHotel,andinvitedmanyindustryexpertstocarryoutnewproductsand

Humen: The 2018 cable show has come to an end!

http://v.youku.com/v_show/id_XMzYxNDQyNTYyMA==.html?spm=a2h0k.11417342.searchresults.dposter

DongguanNanyueMouldDieCastingCo.,Ltd.isparticipatinginthebiennialDüsseldorfInternationalPipe,CableandWireExhibition(April16-20). Ontheseconddayoftheexhibition(April17),theConsulateGeneralofthePeople's

1.GeneralManagerDengNanyuewasselectedas"WininChina" CongratulationstoDengNanyue,GeneralManagerofDongguanNanyueMouldDieCastingCo.,Ltd.,forwinninginChina! Thearticlepublishedin"WininChina"isasfollows: S

(Dongguan,GuangdongProvince):Foreword:InDongguan,thereisalegendary"person",hewascalled"aluminumwheelexpert"bytheindustry.HeisthegeneralmanagerofDongguanNanyueMouldDieCastingCo.,Ltd.(referredtoasNanyue